The Manufacture of Fairings for Competition Motorcycles

Grupo Sicnova signed a collaboration agreement with the Escuela Universitaria Politécnica de La Almunia (EUPLA) to produce the full fairing of an electric competition motorcycle using 3D printing.

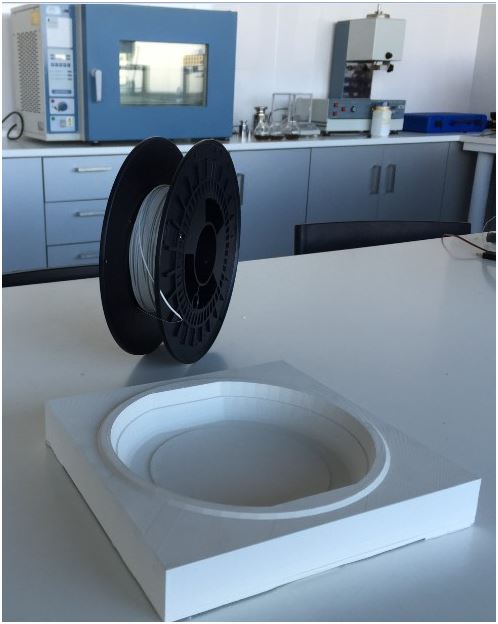

Study of printing technologies

Having taken on board the requirements for the parts, as provided by the team and having analysed the geometry and size of the pieces, the decision was made to manufacture the parts using FFF technology and Easy Print (EP) material because of its mechanical characteristics, its low density compared to other printing materials (so the weight of the fairing will be reduced), the ease of processing the parts and the ease of printing.

Design validation and adaptation

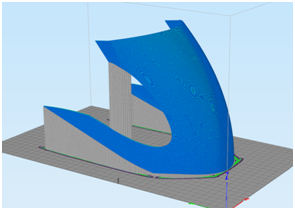

All the pieces have been analysed separately during the design phases and the designers have been advised of the various parameters to be considered when printing, such as the maximum construction angle with no support, the positioning on the flat surface of the part of the piece into contact with the printer dock, etc.

The front fairing has been divided into four parts for the manufacture process:

• Keel

• Left side fairing

• Right side fairing

• Mask

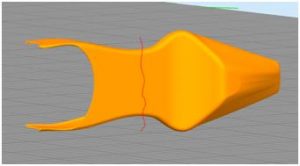

The third distinct part in the fairing is the tail/seat, divided into two parts for manufacturing.

All parts have been manufactured based on similar printing parameters, using the construction material itself (EP) as support material. The printing parameters used are the following:

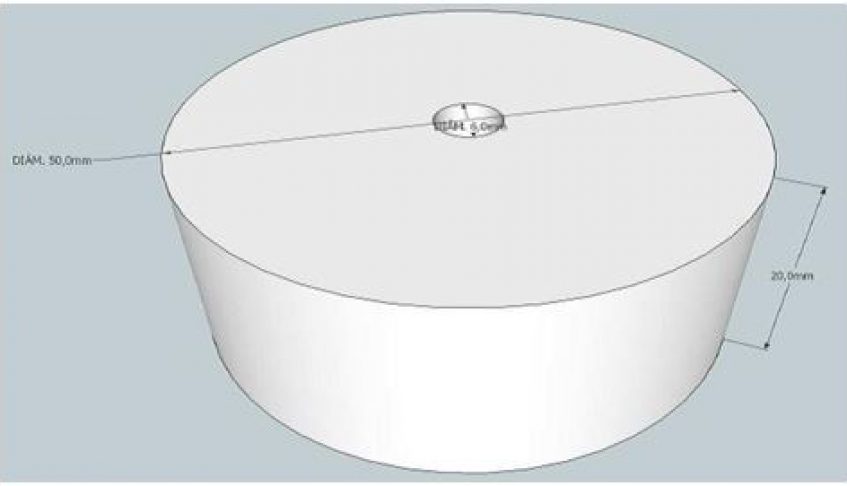

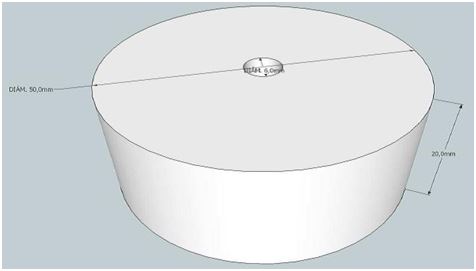

• Nozzle diameter: 0.6 mm

• Layer height: 0.3 mm

• Packing density: 15%

• Number of outer perimeters (walls): 2 (0.6 mmx2 = 1.2 mm)

• Number of upper closing layers: 4 (0.3 mmx4 = 1.2 mm)

• Number of bottom closing layers: 4 (0.3 mmx4 = 1.2 mm)

• Support made with the same material as the construction material, optimized independently, for each part.

Manufacturing

To manufacture the various parts, the Grupo Sicnova JCR 1000 printer has been used following these steps:

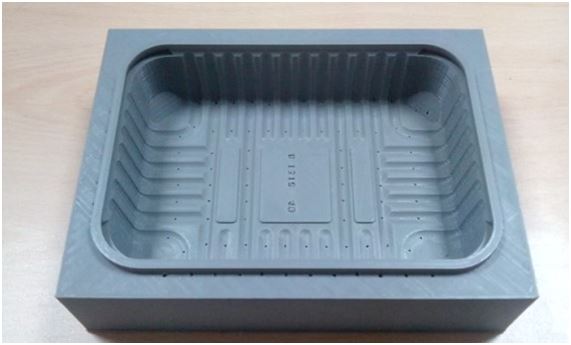

- Generation of printing codes: Using CAM Simplify3D software in order to programme the printing process according to the settings listed above.

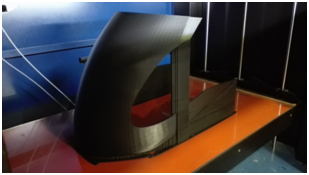

- Manufacturing using a large format JCR 1000 3D printer: The printing code generated is loaded into the printer to launch the manufacture of black EP material, creating the various parts as separate prints.

- Cleaning of the supports: Removal of support structures, previously created and optimized with the help of the Simplify3D software and the experience of the technician responsible for generating a printing code. After the simple removal of the support piece, the connection between the support piece and the material is sanded to remove any residue material from the support.

Assembly and post-processing

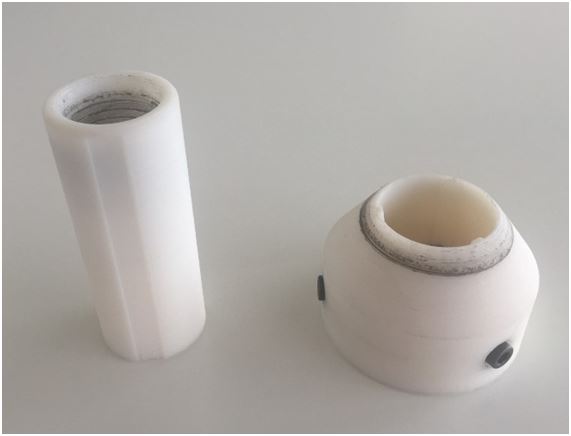

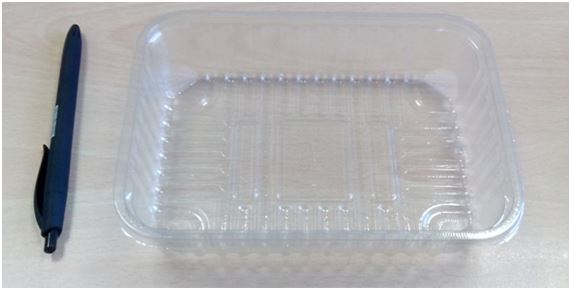

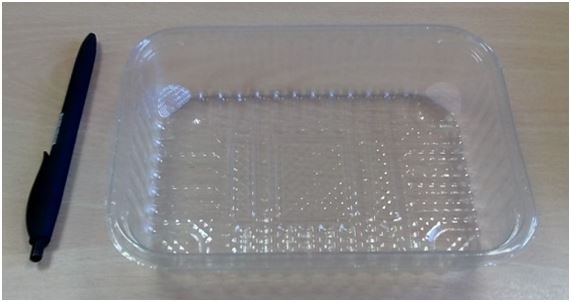

Having manufactured and removed the support, the following step was to assemble the parts that had been separated as part of the design process. To facilitate assembly, the different parts include a series of tabs allowing for a surface overlap between the different parts to reinforce the point of union. See an example below.

Resin was used to join the parts, and a resin with glass fiber was used to reinforce the joints and some parts of pieces which constitute areas of concentrated force, such as the fairing attached to the chassis, which supports the pilot’s weight.

After reinforcing the joints and parts according to specific requirements, we move on to the finishing process. This consists of caulking and sanding the surfaces that have a surface defect, such as the surfaces of points of union between parts.

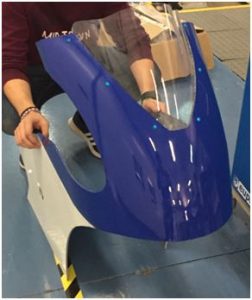

The next step is to prime and sand the parts, thus achieving perfect adhesion of the paint to the piece, and the high-quality and aesthetically pleasing appearance of a completely smooth piece.

Finally, we apply double-layer paint, following the instructions given by EUPLA Racing Team, using the colors requested by the RAL.

Once the parts in the true prototype have been checked, the front flyscreen is fitted and the stickers are added, displaying the bike number and the names of the companies that collaborated on the project.

Evaluation of the results

• The fairing passed all of the various checks and tests it is required to undergo for the MotoStudent competition with no faults.

• The fairing had the necessary flexibility for mounting on the motorcycle, which was an initial requirement set by the team.

• The full fairing weighed less than 10 kg, similar to the fairings conventionally used for these types of motorcycles.

• The motorcycle passed the early ranking stages and achieved a leading position on the starting line.

• After the race, we analyzed how the fairing performed both during the assembly phase and the race, and it was noted that it bore the force and the resistance to which it was subjected in the competition with no problem whatsoever.